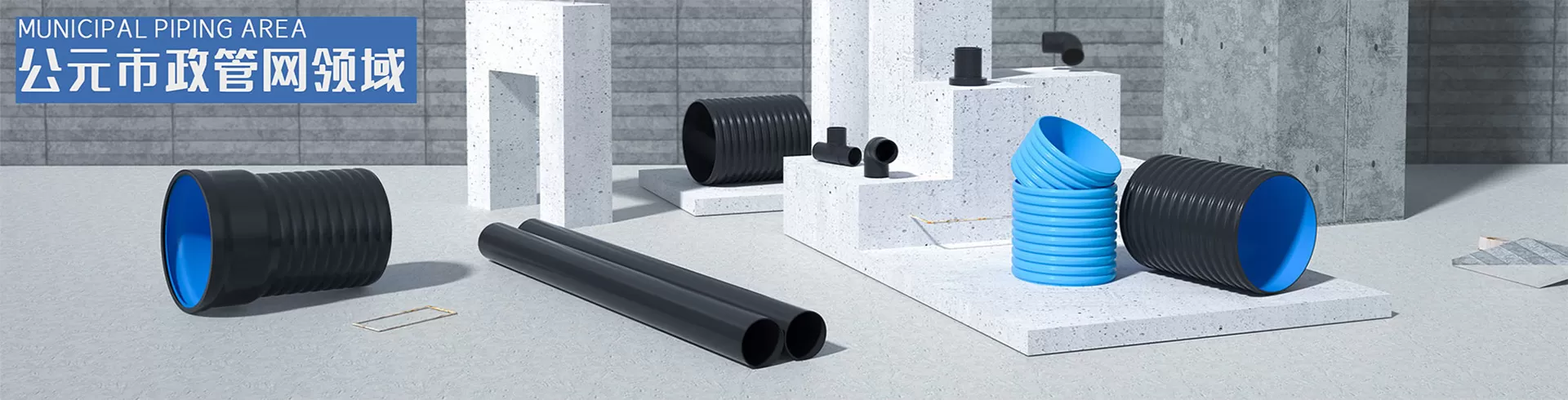

At present, in China's municipal pipe market, plastic pipes are developing steadily. PE pipes, PP-R pipes, and UPVC pipes all have a place. Among them, the strong development momentum of AD PE pipes is the most eye-catching. What is the difference between PE pipes and other commonly used pipes?

PP-R pipe

is also called three-type polypropylene pipe. It has the characteristics of light weight, corrosion resistance, no scaling, and long service life. PP-R pipe is currently the most used water supply pipe in home improvement projects. PPR pipe brands are (national authoritative quality inspection product): At present, the common PPR pipes on the market are AD, Zhongcai, Weixing, Jinde, Liansu, Rifeng, etc. There are many PP-R pipe manufacturers, and there are differences in quality. Once leakage occurs, the loss is huge. It is recommended to choose the well-known AD brand PPR products and choose a professional construction team.

PVC pipe, the full name is Polyvinylchlorid, the main ingredient is polyvinyl chloride, and other ingredients are added to enhance its heat resistance, toughness, ductility, etc. The top layer of this surface film is paint, the main ingredient in the middle is polyvinyl chloride, and the bottom layer is a back-coated adhesive. It is a synthetic material that is deeply loved, quite popular and widely used in the world today. PE pipe for water supply is a replacement product for traditional steel pipe and polyvinyl chloride drinking water pipe.

PE pipe

PE pipe is widely used in a wide range of fields. Among them, water supply pipe and gas pipe are its two largest app stores. PE chemical Chinese name, polyethylene, PE material is widely used in the field of water supply pipe manufacturing due to its high strength, high temperature resistance, corrosion resistance, non-toxicity and other characteristics. Because it will not rust, it is an ideal pipe to replace ordinary iron water supply pipes.

With people's demand for PE pipes, there are various PE pipes on the market now, many PE pipes are not up to Quality Standard, which not only affects the use of consumers, but also affects the quality of the project. Therefore, it is very important to identify the quality of PE pipes.

First, look at the appearance

High-quality PE pipe: the inner and outer surfaces of the pipe are smooth and free of bubbles, depressions, impurities and other defects.

Inferior PE pipe: the inner and outer surfaces of the pipe are not smooth, not bright, there are pits, and there are obvious depressions on the inner and outer surfaces.

Second, milling strip

high-quality PE pipe: oily, smooth, repeated folding is not easy to break.

inferior PE pipe: dark color, folding is easy to break.

third, welding port

qualified welding port should have a smooth and symmetrical flanging along the entire circumference of the pipe, and the minimum depth of flanging should not be lower than the surface of the pipe; weld on both sides of the outer circumference of the flanging at any one of the amount of staggering should not exceed 10% of the pipe wall thickness;

high-quality PE pipe: flanging smooth and flat. After the joint pressure, flanging can be longer.

inferior PE pipe: a large number of pores are generated on the surface after flanging. After the joint pressure, the flanging is short.

IV. Sense of smell

High-quality PE pipe: The product that has just been processed or heated and melted has a slight plastic fragrance, and the product after cooling has no peculiar smell.

Inferior PE pipe: has a pungent smell.

V. Elongation at break

Elongation at break refers to the ratio of the length value of the sample to the original length when it is broken. The higher the elongation at break, the better the flexible type of the product, the better the performance.

High-quality PE pipe: Elongated to 3.5 times without breaking.

Inferior PE pipe: Elongated easy to break, poor toughness.

VI. Oxidation induction time

Oxidation induction time is the time when the automatic catalytic oxidation reaction of the sample starts to occur under high temperature oxygen conditions. It is an indicator for evaluating the thermal degradation resistance of materials in molding processing, storage, welding and use. The longer the oxidation induction time, the better the aging resistance and the better the performance of the product.

Source: Hubei AD Building Materials Co., Ltd., welcome to share! Welcome to contact us to purchase Hubei PE pipe, Wuhan PE pipe, new material water supply, hygiene license.