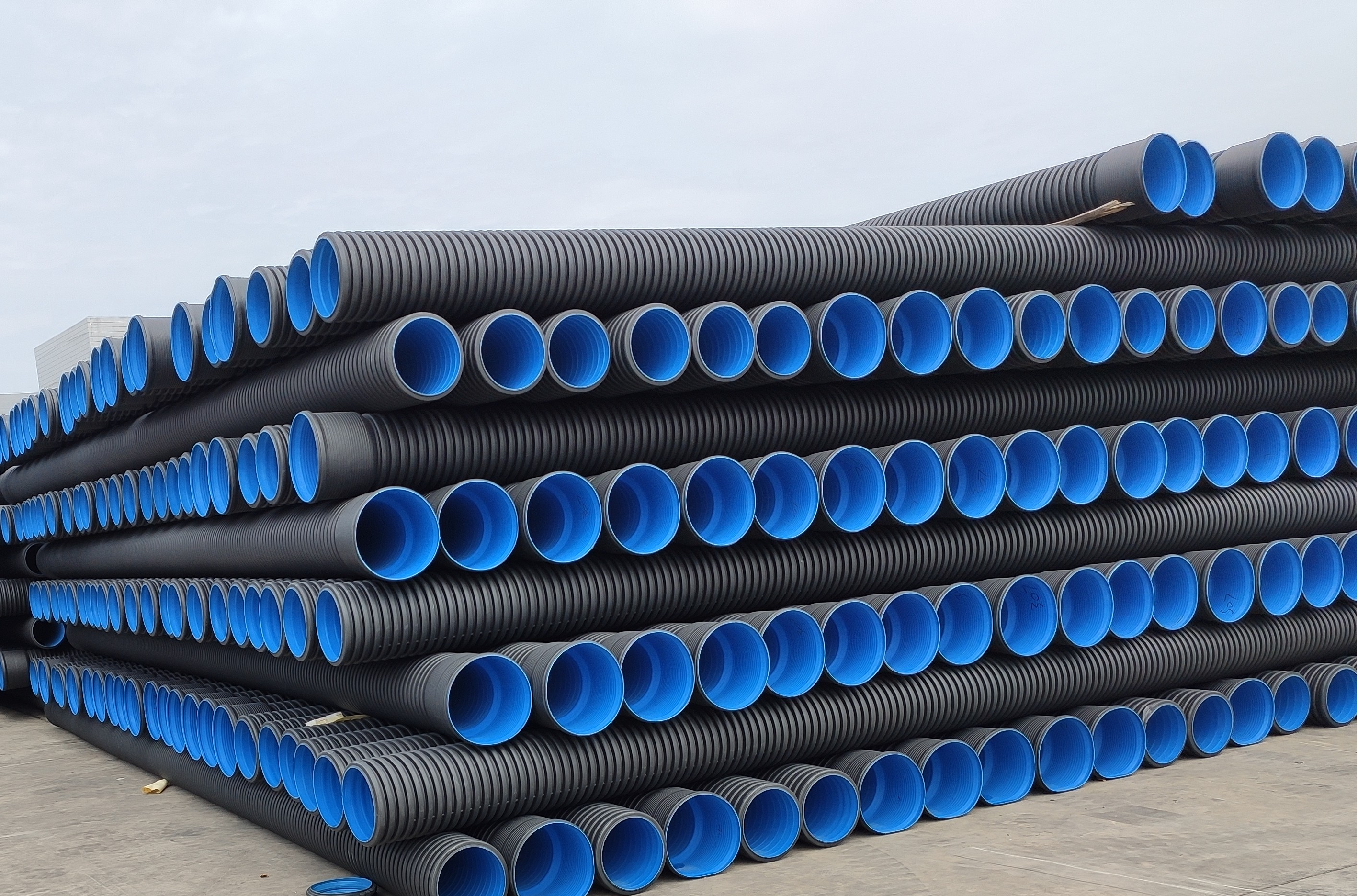

HDPE double-wall corrugated pipes are widely used in municipal sewage pipelines. This article introduces the installation and construction process of double-wall corrugated pipes.

First, the installation and construction procedures of double-wall corrugated pipes

The grooved lower pipe is connected with a closed water and a backfill (implement CECS164:2004 and CECS122:2001 technical regulations)

the grooves of the pipeline

1. The pipeline should be laid on the undisturbed soil foundation or on the treated dense foundation after the grooving. When the pipeline is under the roadway, the thickness of the soil covering the top of the pipe should not be less than 0.7 meters. Groove width: It should be determined according to the outer diameter of the pipe + 0.5m

.

2, when the pipeline passes through the obstacles such as railways, high-grade road embankments and structures, protective casings made of reinforced concrete, steel, cast iron and other materials should be installed.

3, the construction in the rainy season should be as fast as possible to form a groove, backfill fast. - Once the bubble tank, the water should be excluded, the softened soil layer soaked in the bubble should be removed, and the sand and gravel material or medium coarse sand should be replaced.

4, the pipeline adopts sand cushion foundation. For general soil areas, only a layer of sand cushion with a thickness of 10cm should be laid in the base: when the bottom of the tank is below the groundwater level, it is appropriate to lay a layer with a thickness of 20cm

gravel foundation.

The lower pipe of the pipeline, the connection

1, the socket pipe installation should be installed in the direction of water flow, and the water flow direction of the socket channel should be installed in sequence from the low point to the high point.

2, the pipeline installation can be installed manually. The adjustment of the length of the pipeline can be cut with a hand saw, but the section should be vertically flat.

3, when the interface is operated, the inner (or outer) working surface of the socket (or socket) should be cleaned first, put on a rubber ring, check whether the rubber ring is well matched, and apply lubricant to align the center of the socket end with the central axis of the socket.

4, when the socket is inserted into the socket, a wooden baffle can be set at the end of the pipe, and the installed pipe is slowly inserted into the socket along the axis with a crowbar, and installed in sequence. For pipes above 400mm,

can be installed with a cable to tie the pipeline with a manual hoist and other lifting tools. It is strictly forbidden to use construction machinery to forcibly push the top pipe into the socket.

2. Physical properties

Item requirements Test method Ring stiffness SN4 ☺ 4GB/T9647-2015SN8 ☺ 8SN10 ☺ 10SN12.5 ☺ 12.5 Impact performance (TIR)/% ≤ 10GB/T14152-2001 Ring flexible sample smooth, no reverse bending,

No cracking, no disengagement of the two walls

GB/T9647-2015 Oven test No bubbles, no delamination, no cracking GB/T9472.1-2004 3. Product specifications

AD HDPE double-wall corrugated pipe Product specifications Nominal

Inner diameter

Nominal

Outer diameter

Minimum average

Inner diameter

Minimum lamination

Wall thickness

Minimum inner layer

Wall thickness

Bonding 1 , Yonggao double-wall corrugated pipe is the three sub-brands of AD brand, Yonggao brand and Jingjie brand, all of which are national standard double-wall corrugated pipes. The product caliber is from 110 to 1200. Welcome to inquire.

Source: Hubei AD Building Materials Co., Ltd., welcome to share! Consultation hotline: 17399989993