Key points of HDPE double-wall corrugated pipe construction specifications

Hubei AD Building Materials Co., Ltd. As a professional pipe manufacturer, its HDPE double-wall corrugated pipe is widely used in various projects. The following is a detailed introduction to its construction specifications. General regulations

laying foundation: AD pipeline HDPE double-wall corrugated pipe should be laid on the original soil foundation, or after slotting treatment, backfill dense formation. Under the roadway, the thickness of the pipe top covering soil must not be less than 0.7m to ensure the safety of the pipeline. Laying direction: Usually the pipeline needs to be laid in a straight line. If you want to use the flexible interface for line laying, the relative corner at each receiving port should generally not be greater than 1.5 to prevent pipeline damage. Same trough construction: Drainage pipeline projects can be constructed in the same trough, but must strictly follow the design and construction regulations of general drain pipe laying in the same trough. Crossing protection: When the pipeline passes through railways, high-grade road embankments and structures with obstacles, protective casings made of reinforced concrete, steel or cast iron should be installed. The inner diameter of the casing should be more than 200mm larger than the outer diameter of the corrugated pipe, and the end space between the pipe and the casing needs to be filled with fillers to play a protective role. Foundation burial depth: If the buried depth of the pipeline foundation is lower than the bottom surface of the foundation of the building (structure), the pipeline shall not be laid in the compression area of its foundation diffusion angle. Groundwater level treatment: construction in the area where the groundwater level is higher than the bottom elevation of the excavated trench, it is necessary to take measures to lower the bottom groundwater level, and the water level should be reduced to 0.3m - 0.5m below the lowest point of the bottom of the trench before pipeline installation, and the whole process of backfilling cannot stop precipitation to avoid trench instability. Groove related requirements

the width of the bottom of the groove: the net width of the bottom of the trench, which should be determined according to the outer diameter of the pipe plus 0.6m - 1.0m, which is convenient for manual operation at the bottom of the groove. Base excavation: When excavating a trench, the height of the base should be strictly controlled and the base surface should not be disturbed. The original soil of 0.2m - 0.3m above the design elevation of the base should be retained. Before laying the pipe, it should be manually cleaned to the design elevation. If the local overexcavation or disturbance cannot backfill the soil, it needs to be replaced with 10mm - 15mm natural graded sand and gravel material or medium and coarse sand and tamped. Construction in rainy season: Construction in rainy season should shorten the length of the groove as much as possible, so that the groove is formed quickly and backfilled quickly, and measures to prevent foaming tank should be taken. Once the bubble tank is formed, it is necessary to remove the accumulated water, remove the foamed softened soil layer, and replace the sand and gravel material or medium coarse sand for basic treatment. Slotting soil: When manually slotting, it is advisable to stack the mixed soil on the upper part of the tank and the good soil on the lower part of the tank separately for subsequent backfilling, and the soil should not affect Trough bottom treatment: If the trough bottom is buried with blocks, gravel, bricks, etc., which are not easy to remove, it should be removed to 0.2m above the design elevation, and then paving the natural graded sand and gravel material, the surface layer is paved with sand and soil, and the bottom of the trough shall not be soaked or frozen. Basic acceptance: After slotting, it is necessary to check the width of the trough, the thickness of the foundation cushion, the elevation of the foundation surface, the unblocked drainage ditch, whether there is any sludge debris in the ditch, and whether there is any disturbance in the base layer. After passing, the construction can continue. Pipeline installation

installation method: Wuhan bellows pipeline installation is mostly manually installed. For pipes with open grooves and a groove depth greater than 3m or a pipe diameter greater than 400mm, non-metallic ropes can be used to slip the pipe, so that the pipe falls smoothly in the groove pipe position. It is strictly forbidden to use metal ropes to hook the pipe mouth or let the pipe roll from the edge of the groove and throw it into the groove. When installing the socket pipe, the socket is in the direction of water flow, and the socket is in the direction of water flow, and installed in sequence from downstream to upstream. Length adjustment: The length of the pipe can be adjusted by cutting with a hand saw. The cutting section should be vertically flat and not damaged. Connection with the inspection well: There are various connection methods. Flexible interfaces and socket pipe fittings can be used to connect. When the requirements are not high, it can also be directly built into the inspection well wall. Commonly used precast concrete outer ring and rubber ring structure. Before installation, the inner diameter of the outer ring is determined according to the outer diameter of the pipe. The concrete strength is not less than C15 grade, the wall thickness is not less than 50mm, and the thickness is not less than 240mm. First set the rubber ring, insert the pipe material, and then use cement mortar to masonry the outer ring and the well wall. In special areas such as soft soil foundation, first connect the inspection well with a 0.5m short pipe according to the above method, then connect the 2m short pipe, and finally connect the whole pipe. Pipe repair

After the pipe is laid, if the pipe wall is partially damaged, and the length or width of the damaged part does not exceed the circumference of the pipe by 1/12, it can be repaired with Hafu parts. Pipe wall local damage hole is less than 100mm, first set the conjoined rubber ring, and then install the hafu parts and evenly tighten the bolts. Pipe damage is serious, then cut off the damaged part, replace the pipe with equal length and short, with nylon reinforced heat shrinkable belt connection. Backfill requirements

Hubei AD Building Materials Co., Ltd. emphasizes that the pipeline should be backfilled immediately after the installation and acceptance, at least to the top of the pipe double the height of the pipe diameter. The groove from the bottom of the pipe to the top of the pipe within 0.5m range, must be manually backfilled, mechanical bulldozing backfill is strictly prohibited. Pipe top above 0.5m, can be used from both sides of the pipe axis at the same time backfill, tamping or rolling. When backfilling the soil, there should be no stagnant water in the trench, no backfilling with water, no backfilling of mud or organic matter, and no stones, bricks, frozen soil and other miscellaneous hard objects in the backfilling soil. Trench backfilling should be carried out symmetrically on both sides of pipelines, inspection wells and other structures to ensure that pipelines and structures do not move, and limit measures should be taken if necessary. Pipe use

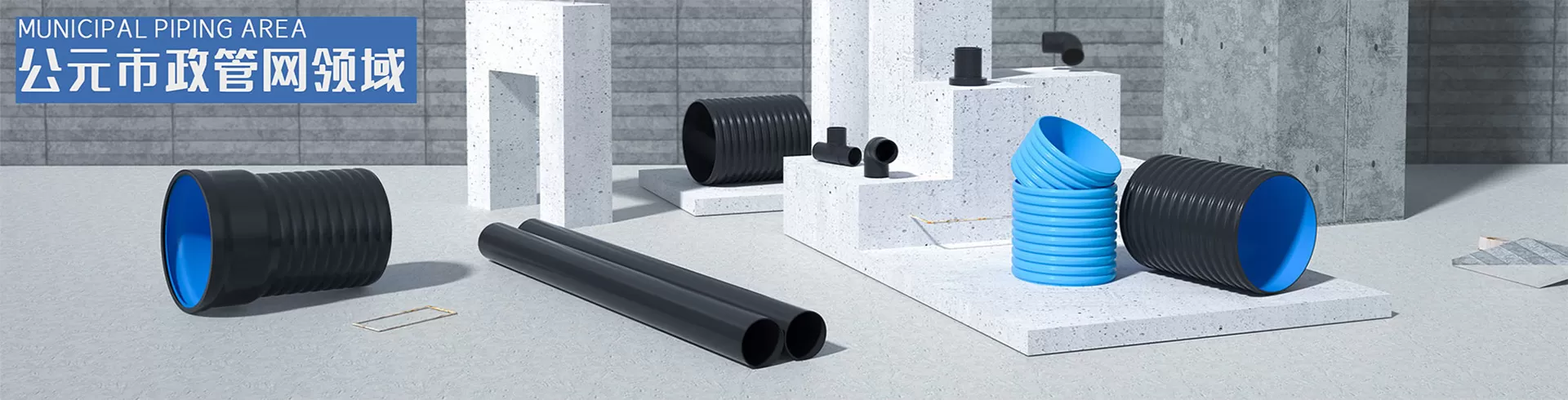

HDPE double-wall corrugated pipe of Hubei AD Building Materials Co., Ltd. is widely used, covering drainage and ventilation of mines and buildings; extranet sewage discharge in municipal and residential areas; irrigation and drainage of farmland water conservancy; sewage treatment plant, waste treatment site drainage and transportation; chemical ventilation and chemical industry, mine fluid transportation; pipeline inspection well overall processing; highway pre-embedded pipeline; high-voltage cable, postal and telecommunications cable protection and other fields, providing reliable pipe solutions for various engineering constructions.